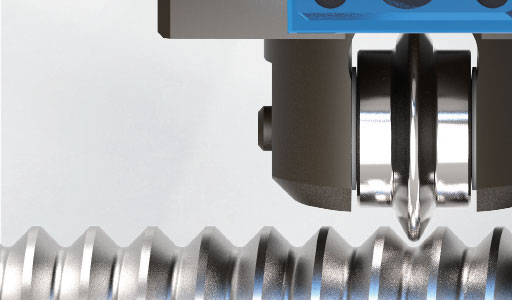

Technical Details: Baublies tool for deep rolling external threads

Burnishing tool for deep rolling of dynamically stressed external threads

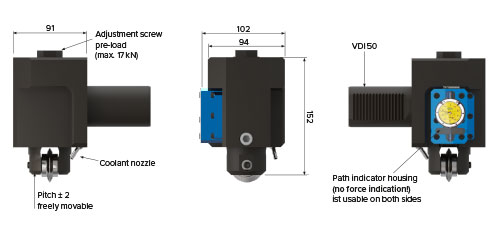

| Application | external threads, deep rolling root of thread |

| Fixture | as required |

| Path indicator housing |

check path indicator (no force indication!) / |

| Roller type |

as required |

Application parameters

Please note that this information represents standard values which must be adapted to the individual cases.

| Speed | up to 200 m/min |

| Feed rate | according to pitch |

| Workpiece allowance | up to 0.02 mm |

| Tool preload | up to 2 mm |

| Lubrication | Emulsion or oil; filtration of the lubricant (< 40 µm) can improve the surface quality and the tool life |

| Pre-machining of workpiece | Surface roughness (Rz) up to 15 µm |

| Workpiece hardneess | up to 45HRC |

You require further information about this specific tool?

Please contact us or send us an e-mail. We will gladly inform you about further details on our tools.

Phone: +49 (0)7159 92 87-90

Burnishing tool for deep rolling of dynamically stressed external threads

In the case of cut threads, the course of the grain of the workpiece is interrupted. With rolled threads, on the other hand, the grain flow is not interrupted, thus the surface of the thread is hardened and the workpiece is less sensitive to notch effects. With the Baublies single roller tool for deep rolling of radii on threads, an increase in the dynamic strength properties can be achieved. The tool rolls the core radius of an external thread and thus hardens the surface. The result is higher wear resistance and reduced notch sensitivity.

ADVANTAGES

- Different roller geometries possible

- Easy replacement of the rollers

- Short processing times

- No set-up and transport costs