Infosheet single-roller burnishing tools

Possible machining contours

VERSATILE USE

Interchangeable single-roller tools and the Baublies modular tool system achieve a significant increase in the material surface hardness in combination with a very smooth surface.

With single-roller burnishing, a hardened roller flattens the surface of the workpiece by contacting it at one single point: In this area of contact the steplessly adjustable roller pressure reaches the yield point of the material. During the process, work hardening of the surface layer and an increase in surface-hardness takes place. The generation of residual compressive stresses significantly increases vibration resistance in the workpiece.

Whether variable, in a modular system or as a tailor made tool, Baublies can provide tooling solutions to suit your specific machining tasks.

Variable single-roller burnishing tools are flexibly adjustable for various contours and can also be used in hard-to- reach places. The rolling unit can be swiveled by 180°.

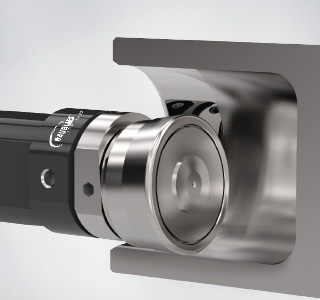

The modular single-roller tool system for lathe machines is an innovative solution for virtually all roller burnishing and roller compression tasks. A basic element is used to mount the interchangeable system components or rolling units.

As a result, the tool can be converted in an extremely short time. This enables special machining tasks to be carried out quickly.

ADVANTAGES

- High flexibility, broad range of applications

- Maximum process reliability

- High-quality and rugged

- Surface roughnesses of under Rz 1.0 µm

- Larger contact area ratios due to plateau formation

- Greater surface resistance to wearing and corrosion

- Constant dimensions and high fitting accuracy

- Shifting of the material fatigue limits

- Low investment

- Fast return of invest

- Environmental sustainability due to a lack of waste products

- The possibility of complete processing in one setting

Single-roller burnishing tool Variable

Modular tool system

Modular tool system

Single-roller burnishing tool for internal-, external-, and taper machining